Pneumatics in the Automotive Industry – Driving Efficiency

Pneumatics play a pivotal role in the automotive industry, significantly enhancing efficiency, safety, and overall vehicle performance. This technology utilizes compressed air to power various tools and systems, revolutionizing how automotive manufacturers operate and how vehicles function on the road. The fundamental principle behind pneumatic systems is the conversion of air pressure into mechanical energy, which is employed in a myriad of applications ranging from assembly line processes to the functioning of specific automotive components. One of the primary applications of pneumatics in the automotive industry is in the assembly and manufacturing processes. Pneumatic tools, such as air impact wrenches, riveters, and drills, are commonly used on production lines to expedite assembly tasks. These tools provide a combination of high torque and lightweight design, enabling workers to complete tasks more efficiently than traditional electric tools. The use of pneumatic systems minimizes downtime and increases productivity, allowing manufacturers to meet the high demands of vehicle production while maintaining quality standards.

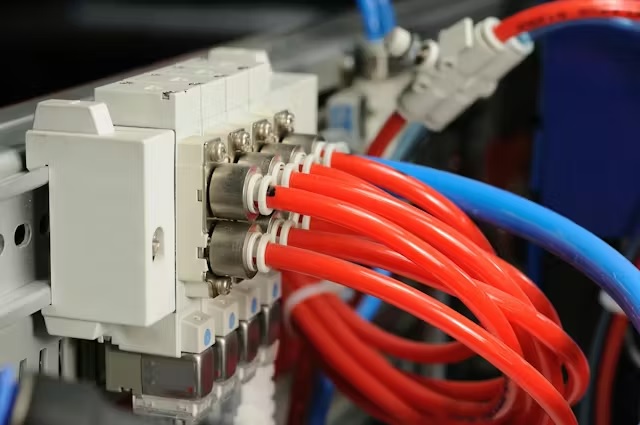

Additionally, because compressed air is readily available in most manufacturing facilities, pneumatics distributor systems are cost-effective and easy to maintain, further contributing to their widespread adoption in automotive assembly. Beyond manufacturing, pneumatics also enhances vehicle performance and safety. In modern vehicles, pneumatic systems are utilized in various applications, such as air suspension systems and braking mechanisms. Air suspension systems adjust the vehicle’s height and improve ride quality by using compressed air to raise or lower the suspension. This adaptability ensures better handling and stability across different terrains, making for a more comfortable ride. Similarly, pneumatic braking systems offer improved responsiveness and safety. They can apply a significant amount of force with minimal delay, allowing for quicker stops and better control, especially in heavy vehicles such as trucks and buses. Moreover, pneumatic technologies contribute to environmental sustainability in the automotive industry. As manufacturers strive to reduce their carbon footprint, the efficiency of pneumatic systems can lead to significant energy savings.

Compressed air systems, when designed and maintained correctly, can operate with minimal energy waste. Furthermore, the use of air-powered tools reduces reliance on electricity and fossil fuels, aligning with the industry’s shift towards greener practices. This emphasis on sustainability is becoming increasingly important as consumers demand more environmentally friendly vehicles, prompting automakers to adopt innovative technologies that reduce emissions and promote energy efficiency. In addition to these practical applications, the integration of advanced pneumatic systems in automotive engineering is pushing the boundaries of what is possible. Innovations in automation and smart technologies are enabling more sophisticated pneumatic solutions, such as predictive maintenance and real-time monitoring. These advancements not only improve the reliability of pneumatic systems but also enhance their overall efficiency and read this article pneumatig.eu. For instance, sensors can monitor air pressure and detect leaks, allowing for timely maintenance that prevents downtime and costly repairs. In conclusion, pneumatics is a vital component of the automotive industry, driving efficiency and innovation across manufacturing and vehicle operation.