CNC Services Offer Tight Tolerances And Dependable Part Reproduction

CNC services have become an essential part of modern manufacturing, offering exceptional precision and reliability that traditional machining methods often struggle to match. One of the most significant advantages of CNC Computer Numerical Control machining is its ability to achieve tight tolerances. This precision is critical in industries where even the smallest deviation from specifications can lead to part failure or compromised performance. Tight tolerances ensure that each component meets exact dimensions and specifications, which is particularly important for applications in aerospace, medical devices, automotive, and electronics manufacturing, where quality and safety standards are incredibly high. The tight tolerances achievable through CNC machining stem from its automated nature and advanced programming capabilities. Unlike manual machining, CNC machines operate using detailed digital designs that control the cutting tools with incredible accuracy. This results in consistent part production where every piece is virtually identical to the next, eliminating variability caused by human error. The precision offered by CNC technology means manufacturers can produce intricate components with complex geometries and fine details that would be nearly impossible or prohibitively expensive to create manually.

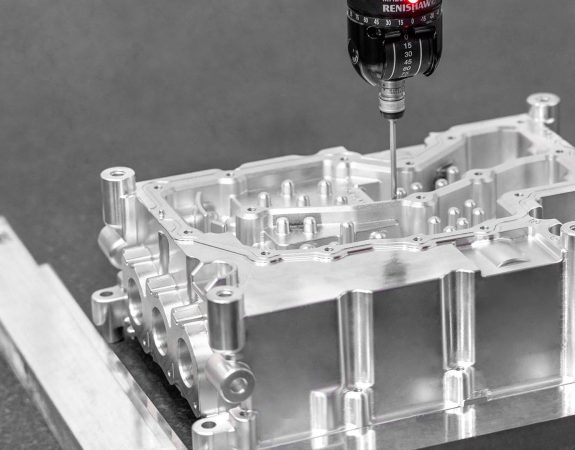

Additionally, CNC machines maintain repeatability, meaning the same part can be reproduced countless times without losing quality or dimension accuracy. Dependable part reproduction is another cornerstone of CNC machining services. In manufacturing, producing parts that consistently meet quality requirements is essential for maintaining product integrity and reducing waste. CNC machines excel in this regard because they follow exact instructions from CAD Computer-Aided Design files, ensuring every cut and movement is executed precisely as programmed. This consistency reduces the risk of defects, scrap parts, and rework, which ultimately saves time and costs for manufacturers. Moreover, CNC machines can quickly switch between different jobs and designs while maintaining the same level of precision, allowing businesses to be more flexible and responsive to market demands. Furthermore, CNC services often incorporate various quality control measures throughout the manufacturing process. Advanced CNC setups may include in-process inspections and feedback systems that monitor tool wear, alignment, and cutting conditions in real-time. These systems help maintain tight tolerances and ensure that each part meets or exceeds specifications before moving on to subsequent production stages.

The result is a highly dependable manufacturing process that guarantees high-quality outcomes and minimizes the chances of defective parts reaching customers. The ability to produce parts with tight tolerances and dependable reproduction also supports rapid prototyping and low-to-medium volume production runs. CNC machining enables manufacturers to test designs with functional prototypes that accurately reflect the final product, allowing for adjustments and improvements before committing to large-scale manufacturing. This capability speeds up product development cycles and reduces the risk of costly mistakes. Additionally, online cnc service can easily accommodate design changes without extensive retooling, further enhancing manufacturing efficiency. This combination is vital for industries requiring high-precision components that perform reliably in demanding environments. The precision, repeatability, and flexibility of CNC machining not only ensure superior product quality but also enhance manufacturing efficiency and cost-effectiveness. As technology continues to advance, CNC services will remain a key driver of innovation and quality in modern manufacturing processes.